Quality Assurance for Warehoused Finished Products

The starch is placed on the pallet and inventory management is strictly strengthened.

The produced starch is piled up orderly on the pallet to ensure moisture-proof and safe storage. Batch management is strengthened and warehouse-in and warehouse-out follows the principle of “First-in First-out” (FIFO).

Warehouse Thermometer and Hygrometer

Real time record and summarize the temperature and humidity of the warehouse. Analyze how the warehouse temperature impacts on the starch and keep continuous improvement.

Rat-proof Devices

The warehouse has such rat-proof devices as rat repeller, glue rat board and rat cage) to ensure safe storage of starch.

Continuous Improvement for Packaging Material

The packaging materials and their layouts are continuously improved to ensure moisture-proof, tidiness and product safety and thus to satisfy customers’ demands.

Quality Assurance for Warehoused Finished Product

Starch storage management

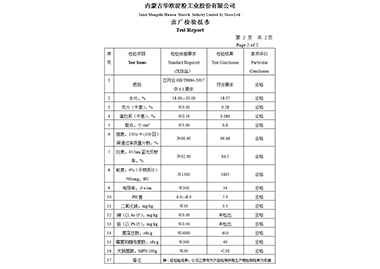

Ex-factory Inspection for Finished Product

Use belt conveyors for conveying finished products.

Use belt conveyors for product loading to reduce packaging damage and greatly increase work efficiency.

Marketing Network